Electric arc furnaces to reduce steelmaking emissions

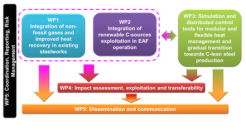

The indispensability of steel in society and the need to protect the environment are at the basis of the steelmaking industry's decarbonisation. Clean steelmaking transition finds in electric arc furnaces (EAF) a key technology: it is at the basis of scrap-based steelmaking (a circular economy process) and of the new DRI-EAF route that is expected to replace the BF-BOF route. In this context, the EU-funded GreenHeatEAF project aims at further increasing the importance of EAF. The replacement of natural gas and other fossil energy sources with hydrogen or renewable carbon sources (e.g. biochar) is investigated. In addition, technologies to re-optimise the heating management with maximum heat recovery from off-gas and slag are explored. Coupling pilot tests with digital applications constitutes the strength of GreenHeatEAF.