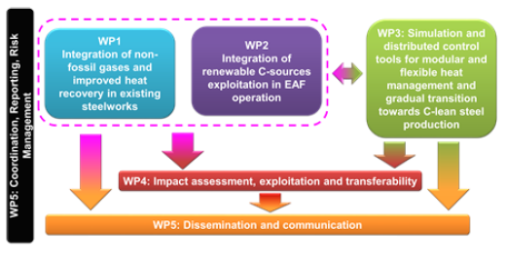

WP1 : Integration of non-fossil gases and improved heat recovery in existing steelworks

WP1 deals with investigations related to the usage of H2 and NG-H2 blends in EAF process; standard and cutting-edge EAF burners are tested in pilot and on field trials, simulations support the trials. The effect of H2 on the process are evaluated and different charge materials and modes are explored. WP1 activities are completed by tests of heat recovery solutions from off-gases and slags generated during trials, by taking advantages from innovative sensors and heat recovery technologies and processes.

Key objectives:

- Demonstration of hydrogen enhanced combustion (HEC) for EAF heating by using standard EAF burners.

- Demonstration of hydrogen use in EAF using CoJet-technology in TRL7 for different use cases.

- New overall gas phase conditions using HEC (Simulation)

- Off-gas temperature and heat recovery monitoring system

- Demonstration of regenerative/recuperative heating of gases using EAF off-gas

- Evaluation of hot treatment of new EAF slag

WP2: Integration of renewable C-sources exploitation in EAF operation

WP2 is related to the study of the effects of biomass/biochar use in EAF; pilot, demo and simulation investigations are provided after a study of available biomass on the market and selection of most suitable ones.

Key objectives:

- Determination of the most suitable biomass/biochar to be used in the EAF considering their performance and effect on the process and facility.

- Simulation of the metallurgical process when using different types of biomass/biochar to study its effect during the melting of steel and to optimise its usage.

- Demonstration of the technical feasibility of using biomass/biochar instead of fossil fuels in the EAF operation.

WP3: Simulation and distributed control tools for modular and flexible heat management and gradual transition towards C-lean steel production

WP3 is a tranversal WP including modelling and simulation activities further supporting WP1 and WP2 trials and extending their investigation horizon, considering aspects that can optimize the integration of GreenHeatEAF solutions and technologies in existing and future steelworks. Advanced control strategies are developed and a roadmap is provided for gradual and optimal integration of GreenHeatEAF solutions and technologies in view of steelworks C-lean transition.

Key objectives:

- Adapt process models to support the integration of GreenHeatEAF solutions

- Integrate novel measurement techniques to fill gaps in monitoring needs for off-gas

- Develop control tools for decarbonised modular and hybrid EAF heating

- Create roadmap towards C- lean steel production for optimizing the integration of GreenHeatEAF solutions and looking beyond the project results

WP4: Impact assessment, exploitation and transferability

WP4 is devoted to the assessment and monitoring of GreenHeatEAF solutions and technologies impact on environmental, economic and social impacts. WP4 includes also activities aimed at ensuring exploitation and replication of the project results, solutions and technologies.

Key objectives:

- Assessing the impact of GreenHeatEAF on CO2 emissions reduction of the steel production chain.

- Life Cycle Assessment (LCA) to assess the overall environmental performance of the GreenHeatEAF solu-tions and technologies.

- Assessment of the social impact of GreenHeatEAF.

- Definition of the strategy for result exploitation focusing on IPR management among partners.

- Development of a business model for the project KERs.

WP5: Dissemination and communication

WP5 targets dissemination and communication of the project outcomes.

Key objectives:

- Develop a Dissemination and Communication (DC) strategy and plan for different target groups

- Continuously monitor the DC plan and execute appropriate DC measures to address right target groups

- Carry out engagement and interaction activities with other CSP projects and external key stakeholders

WP6: Coordination, Reporting, Risk Management

WP6 is dedicated to project and risk management, reporting and coordination.

Key objectives:

- Deliver project on time and on budget and ensure an effective and efficient progress;

- Deal with administrative and financial management of the project;

- Perform continuous evaluation and monitoring of the technical/impact content of the project;

- Secure consistent high quality of the work to be performed and of the reports produced;

- Manage risks and issues effectively;

- Develop overall legal, contractual, and ethical management of the project.