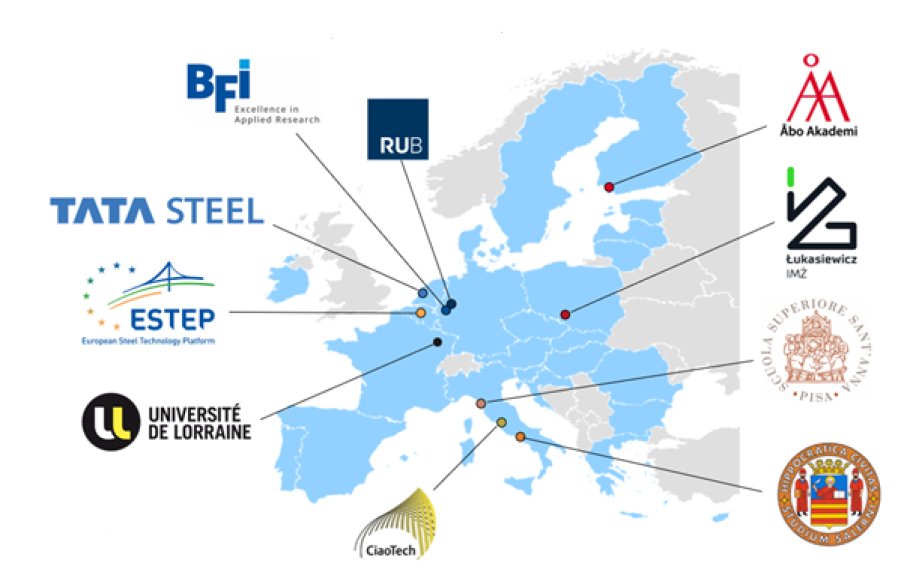

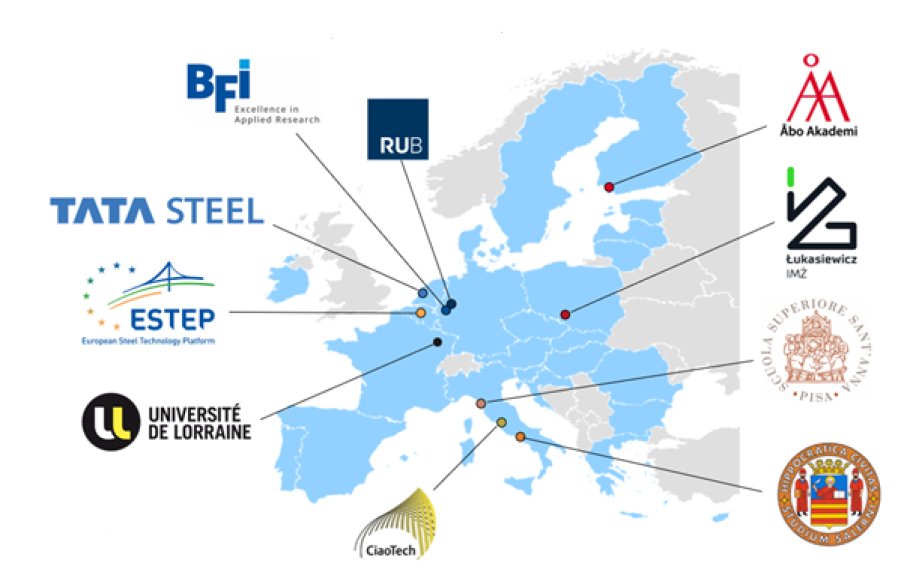

The MaxH2DR consortium consists of 10 specialised partners (1 steel producer, 3 research institutes, 5 universities and 1 technology platform) from 7 different EU countries. The MaxH2DR project is coordinated by SSSA ( overall project coordination) and BFI (technical coordination).

VDEh-Betriebsforschungsinstitut GmbH (BFI)

VDEh-Betriebsforschungsinstitut GmbH (BFI), a non-profit institute in Germany, is focused on applied research for steel industry. The staff of around 100 people is organised in 8 scientific departments and drives in close and interdisciplinary cooperation. 70% of the staff are scientists and engineers who guarantee, together with technicians and administrative staff, a high level of research quality and project performance e.g., by applying a strict quality management of research proposals and a consequent results-oriented management of projects.

Ruhr-University Bochum

Ruhr-University Bochum (RUB) is one of Germany’s leading research universities. The University draws its strengths from both the diversity and the proximity of scientific and engineering disciplines on a single, coherent campus. RUB is the largest employer in Bochum (6.200) and one of the largest universities in Germany in terms of students (42.000). RUB has an in-house DEM code which is perfectly suitable for the project.

Université de Lorraine

The Université de Lorraine (UL), a big university in the West of France, trains 60,000 students and employs 7,000 people. The university is multidisciplinary and international (10,000 international students). It is also a member of several European networks, and is 43rd in the Shanghai ranking in metallurgical engineering. Institute Jean Lamour (550 people) is the laboratory committed to MaxH2DR, with its ‘Process metallurgy' group. The University of Lorraine has long experience in DR modelling.

Scuola Superiore di Studi Universitari e di Perfezionamento Sant'Anna (SSSA)

Scuola Superiore di Studi Universitari e di Perfezionamento Sant'Anna (SSSA) is an autonomous, special statute public university operating in the field of applied sciences. SSSA achieved the top positions in the World University Rankings such as the 7th position in the Times Higher Education Young University Ranking 2021 on a census of 1527 institutions. SSSA trains almost 1200 bachelor, master and phd students with a number of about 90 professors and a research staff of about 320 people. SSSA will participate to the project through the centre of ICT for Complex Industrial Systems and Processes (ICT-COISP) of the Institute of Communication Information and Perception Technologies (TeCIP). Since its origin, this team of 15 multidisciplinary researchers (i.e. chemical, energetic, automation and telecommunication engineers, informatic scientists, biologist, some of them with PhD in robotics or emerging digital technologies) focuses its activity in the steel sector, particularly by applying Artificial Intelligence (AI) and advanced modelling systems for the monitoring, management, optimization and control of processes for steel production as well as steel products quality monitoring, enhancement and optimization across the whole process chain.

Åbo Akademi University

The Process and Energy Technology cluster of Åbo Akademi University (AAU) in Åbo, Finland, has strong scien-tific merits and industry collaboration, focusing on energy technology, chemical reaction engineering, and process systems analysis and sustainability. Professor Saxén’s group, which has studied ironmaking technology since 1983 and published 130 journal papers on this topic, will collaborate with Prof. Henrik Grénman’s team that provides top expertise in chemical kinetics to MaxH2DR.

Tata Steel

Tata Steel is Europe's second largest steel producer, with steelmaking in the UK and Netherlands, and manu-facturing plants across Europe. The company supplies high-quality steel products to the most demanding markets, including construction, automotive, packaging, rail, lifting & excavating, energy and aerospace. The combined Tata Steel group is one of the world’s largest steel producers, with a steel capacity of more than 28 million tonnes and 80,000 employees across five continents. Tata Steel R&D has experimental facilities and testing apparatus specifi-cally designed and validated for testing of burden materials under simulated furnace conditions, together with expe-rienced technologists to evaluate the tests and also decade-long experience in all aspects of the related applied re-search.

University of Salerno

The University of Salerno (UNISA) participates in this project with the group of Powder Technology of the De-partment of Industrial Engineering of University of Salerno, section of Chemical Engineering. UNISA is one of the largest universities of southern Italy with 16 Departments and 2 campuses more than 40000 students. The Depart-ment of Industrial Engineering is made of 88 faculty members carrying out cutting edge research in the areas of Health, Food, Agriculture and Biotechnology, Information and Communication Technologies, Nanotechnologies, Materials and New Production Technologies Energy, Environment, Transports and is very experienced in investi-gations of bulk flow properties related to industrial engineering,

Łukasiewicz Research Network ̶ Institute for Ferrous Metallurgy

Łukasiewicz Research Network ̶ Institute for Ferrous Metallurgy (IMZ), Poland, is rendering scientific research, consulting and training services for steel producers, steel users and institutions involved in the steel business. 71 employees are involved in research activity, of which the experienced research staff counts: 26 employees – with PhD title, 7 employees – as associate professor, 4 employees – with scientific title of professor. In total, 44 people are employed in scientific and research and technical positions, including 2 PhD students and 24 people in engineering and technical positions. The main research activity of the Institute covers: research and improvement of technological processes, production processes of hot metal, steel as well as semi products and finished steel prod-ucts, semi-industrial, physical and numerical simulation methods of metal products manufacturing processes, mod-elling of microstructure and mechanical properties of products.

CiaoTech

PNO (here with its Italian branch CiaoTech) is a 400 professionals’ group with direct presence in 7 countries , specialized in Innovation Management, R&D Advisory and funding procurement, providing support services to private and public bodies. PNO is part of the experts for the Horizon Results Booster and will support exploitation activi-ties, also adopting its own IT tools and methodologies. It will also generate its own exploitable results by completing a thorough market outlook and technology intelligence and publishing it.

European Steel Technology Platform

The European Steel Technology Platform (ESTEP) comprises major stakeholders in the European steel industry. Members are major steel manufacturers; universities and research institutions active in steel research; major users of steel such as car manufacturers; and public bodies like the European Commission and national governments. The technology platform, located in Belgium, is focused on the support of collaborative research and innovation in the European steel industry.

This project has received funding from the European Union under grant agreement NUMBER — 101058429 — MaxH2DR

This project has received funding from the European Union under grant agreement NUMBER — 101058429 — MaxH2DR

The information and views set out in this webpage do not necessarily reflect the official opinion of the European Commission. The European Commission does not guarantee the accuracy of the data included in this webpage. Neither the European Commission nor any person acting on the European Commission’s behalf may be held responsible for the use which may be made of the information contained therein.